ABOUT US

INNOVATIONS

Our designers are constantly looking for new solutions in architecture and construction, which would be in accordance with nature and the environment around us. The construction industry is available in an increasing material diversity and higher technical capabilities that we rapidly implement and use in the projects. For example, panels made of cross laminated timber allow to develop a new product – dynamic modular system, which we offer to our clients.

In 2018, we will continue to implement innovations. We will offer to implement virtual reality applications that will allow both residents and municipalities to order the construction of a house. For this opportunity the more it will be possible to learn, by following along the section News on our site.

Our innovation projects

POLYMER CONCRETE

Polymer concrete is an environmentally friendly alternative to widely used construction material - cement. Polymer concrete is a substitute for all conventional cement-based concrete. Polymer concrete is more durable to an active, aggressive environment, therefore, it is especially suitable for pavements, shafts, road slabs and outdoor products. Research has shown that a number of polymer concrete technical parameters are higher than that of the widely used cement. For example, the strength of a polymer can be up to 10 times higher than that of traditional concrete. Polymer concrete is obtained by replacing some of the raw materials with recycled plastic waste and dolomite eaves, which is a particularly innovative technology across Europe. Using this technology, we can successfully compete with the price of cement, offering even lower prices than traditional concrete.

Polymer concrete products

Plates, borders, etc. are made from polymer concrete. There are traditionally concrete products. The advantage of a polymer concrete product is its higher aggressive strength, for example in a humid environment, lower cost than cement and also eco-friendly technology. Polymer concrete products will be available from summer of 2018.

Polymer concrete manufacturing technology

Polymer concrete production technology is an innovation in construction in both the Baltic and EU countries. From mid-2018, we will also give our customers the opportunity to purchase polymer concrete production equipment. Polymer concrete production equipment is based on our and "JPMK Polymer Concrete" llc. combined innovative polymer production technology. This technology will enable entrepreneurs, local authorities, landfills, etc. to use recycled plastic waste in the manufacture of polymer concrete. At present, there is a possibility to manufacture polymer concrete from high quality, high cost raw materials on the market. We offer technology that will enable this material to be produced from low-cost, recyclable waste materials, thus saving significantly and selling products at a lower price than competitors. Advantages of polymer concrete technology: lower costs of polymer concrete, lower production costs; green technology Implementation and sale: products available starting mid-2018.

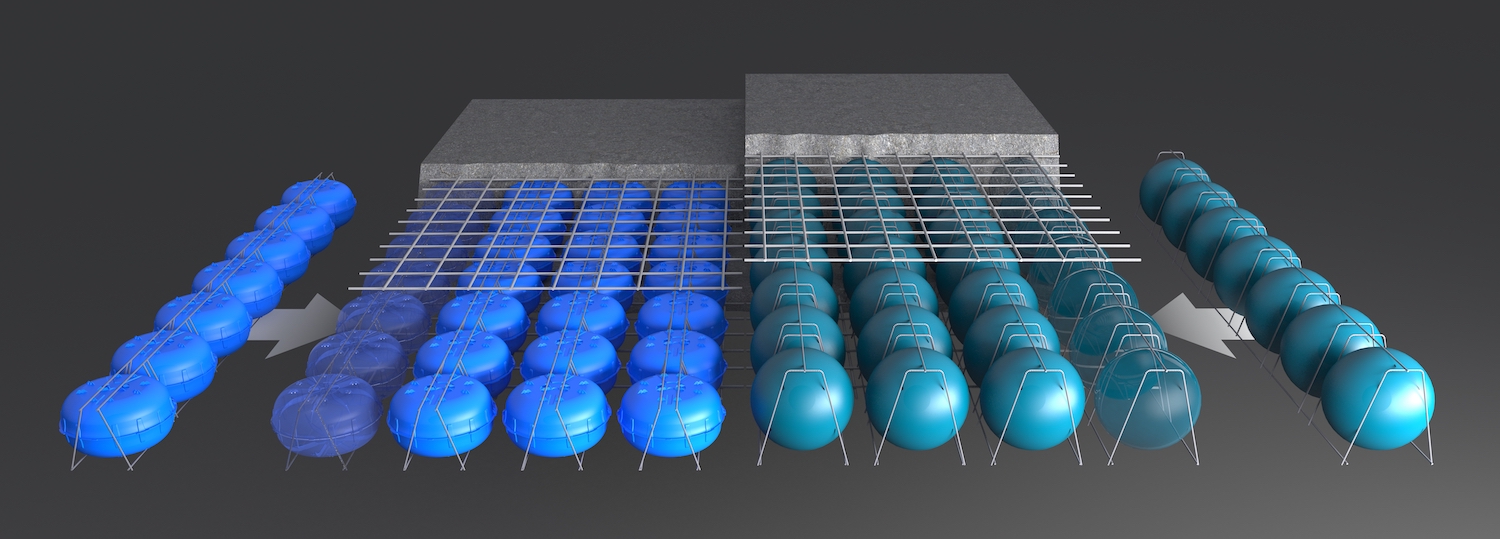

COBIAX

January 17, 2018 in Wiesbaden (Germany) Jēkabpils PMK company signed a letter of intent to cooperate with Cobiax company and became the official Salespartner of Cobiax.

German scientists and engineers of Cobiax have developed innovative systems, with which it becomes possible to facilitate reinforced concrete structures, reducing the consumption of concrete and creating new engineering opportunities in construction. On the basis of the agreement, Jēkabpils PMK has started a new innovative stage in the development of reinforced concrete products! Cobiax has developed special voidforming modules. This technology is based on special "spheres" installed inside reinforced concrete slabs or when pouring monolithic concrete. A large part of the concrete is replaced by these voidformers, they remain in the concrete forever. Thus, it is possible to construct buildings with lighter plates, while providing a significant width of spans.

It is environmental and efficient technology that reduces CO2 emissions by up to 20 percent. Cobiax products are made from 100% recycled plastic.

The system of voidforming modules, which is built into reinforced concrete structures, reduces their weight. Using this system, you can reduce the load to 35 percent, as well as replace expensive building materials, firstly the concrete itself. You can reduce not only the cost and quantity of materials, but also protect the environment.

This is an internationally patented and tested technology, the production is in Germany. Cobiax has developed two product lines - Eco-Line and Slim-Line – economical, environmentally-friendly and universally used voidformers for the manufacture of concrete slabs and monolithic structures.

WATERPROOFING MATERIALS FROM RECYCLED ENGINE OIL AND HYDRAULIC OIL

Waterproofing materials

Piedāvāsim iegādāties hidroizolācijas materiālus, kas iegūti pārstrādājot tādus toksiskos atkritumus kā motoreļļu un hidroeļļu. Šādu hidroizolācijas materiālu priekšrocības ir lētākas cenas, nekā pašlaik tiek piedāvāts tirgū; augsta kvalitāte; videi draudzīga ražošanas tehnoloģija. Produkcija būs pieejama sākot no 2018. gada vidus.

Materials production technology

Mūsu piedāvātā tehnoloģija ļaus pārstrādāt tādus toksiskos atkritumus kā izlietota motoreļļa un hidroeļļa, tās pārveidojot hidroizolācijas materiālos. Piedāvātā kaitīgo atkritumu pārstrādes iekārta ļaus uzņēmumam ietaupīt un tālāk pārdot produkciju ar augstu pievienoto vērtību. Kaitīgie atkritumi: Hidrauliskā eļļa; vecā/nolietotā motoreļļa kļūst par vērtīgu izejvielu. Piedāvātās hidroizolācijas ražošanas tehnoloģijas priekšrocības: zemākas izejvielu un ražošanas izmaksas; videi draudzīga tehnoloģija. Iekārtas būs pieejama sākot no 2018. gada rudens.

THE MOBILE CONSTRUCTION WASTE PROCESSING EQUIPMENT

Piedāvājam iegādāties skaldāmo būvgružu ( betons, stikls un citi) pārstrādes iekārtu. Iekārta ļauj no būvgružiem iegūt atkal izmantojamus beramos materiālus. Iekārtas priekšrocības: mobila/pārvietojama iekārta; ļauj realizēt būvgružus to utilizācijas vietā; videi draudzīga tehnoloģija. Iekārta būs pieejama no 2018.gada vidus.

INNOVATIVE BUILDING CONSTRUCTION SYSTEM

Izmantojot modernu un tradicionālu būvmateriālu priekšrocības, kā arī savstarpējā mijiedarbībā neitralizējot to trūkumus, sadarbībā ar “Knauf” un “Paroc” izstrādāta augstas rūpnieciskās gatavības, standartizētos konstruktīvos risinājumos balstīta ēku būvniecības metode. Inovatīvās būvniecības sistēmas pamatā ir krustiski līmētās masīvkoka plātnes apvienojumā ar tērauda profilu nesošajiem elementiem, kas būvē ļauj realizēt lielākus laidumus nekā tradicionāli, tādā veidā dodot lielāku brīvību ēkas plānojumam un tā piemērošanai mainīgajiem dzīves apstākļiem. Sistēma paredz lietot saliekamus polimērbetona plākšņu pamatus, kas līdz minimumam samazina zemes darbus un, atbilstoši Latvijas būvnormatīvos paredzētajiem būvniecības veidiem, ir novietošana. Piedāvātā būvniecības sistēma nodrošina augstu energoefektivitāti un rūpniecisko gatavību, līdz minimumam samazinot darbus būvlaukumā. Izmantojot “Knauf” sistēmas, tiek panākta nepieciešamā ugunsdrošības pakāpe. Izstrādātā būvniecības metode nodrošina plašu funkcionālo pielietojumu un ar to iespējams realizēt praktiski jebkuru arhitektūras ieceri.

Piedāvātā inovatīvā būvniecības metode iedzīvina dinamiskās mājas koncepciju (sauktas arī par "moduļu mājām" vai "moduļu ēkām"), tas nozīmē māju kas gan aug, gan dilst un mainās, piemērojoties īpašnieku mainīgajām vajadzībām un iespējām. Sistēma ir piemērota arī augstas rūpnieciskās gatavības savrupmāju būvniecībai kā arī sabiedriskajiem objektiem (nelielas sporta un saviesīgas zāles, veikali, tirgi u.c.) birojiem un pat daudzstāvu apbūvei. Būvniecības metode būs pilnībā pieejama no 2018.gada, masu pārdošanā: no 2018.gada vidus.

Projekta vadītājs, arhitekts

Guntis Kārkliņš

Tālr. 29109518

E-pasts: This email address is being protected from spambots. You need JavaScript enabled to view it.

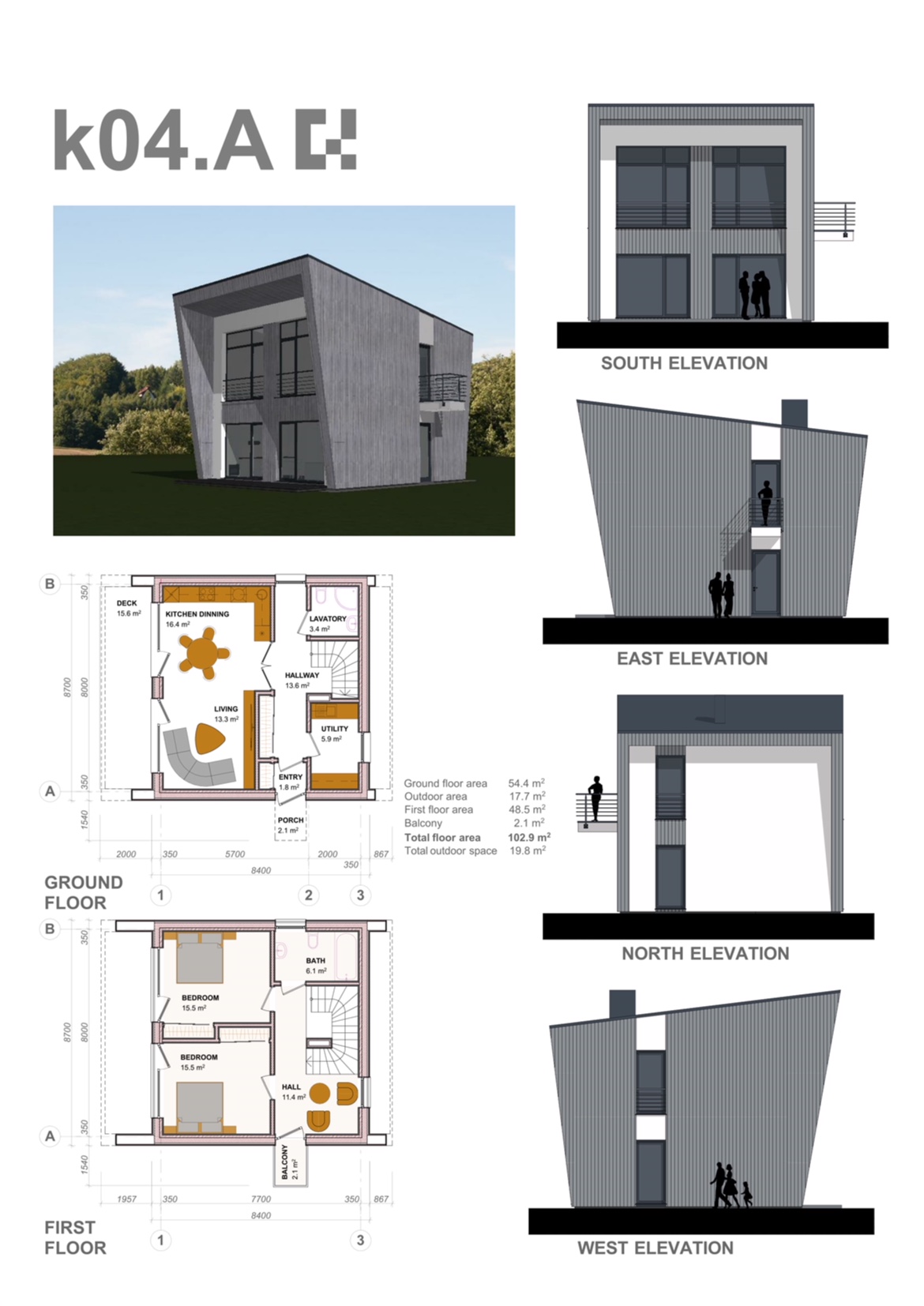

DYNAMIC HOUSES KITS

DETACHED HOUSES

PUBLIC OBJECTS

Realized projects with new technologies

ENERGY EFFICIENT MODULAR HOUSE

We have built the first energy-efficient modular home! The construction is based on the relaxing foundations that provide concrete austerity. The walls are constructed from "Paroc" LLC, a new Finnish technology for ventilated facades and innovative CLT (cross-laminated timber) slabs. The roof and walls are insulated with Paroc wadding.

"Knauf" LLC has developed sound and fire safety efficiency in the interior. This dynamic house is close to the passive home concept - created with high construction and thermal efficiency.